The galvannized steel 46KG Filter Fan Unit from Amber is a high-efficiency air purification device that integrates a fan and a high-efficiency filter. It can effectively filter particles above 0.3μm and ensure that the indoor cleanliness is stable at Class 100.

The FFU Fan Filter Unit is widely used in modular operating rooms, pharmaceutical clean workshops, electronic semiconductor factories and laboratories to meet the air purification needs of different high-cleanliness environments.

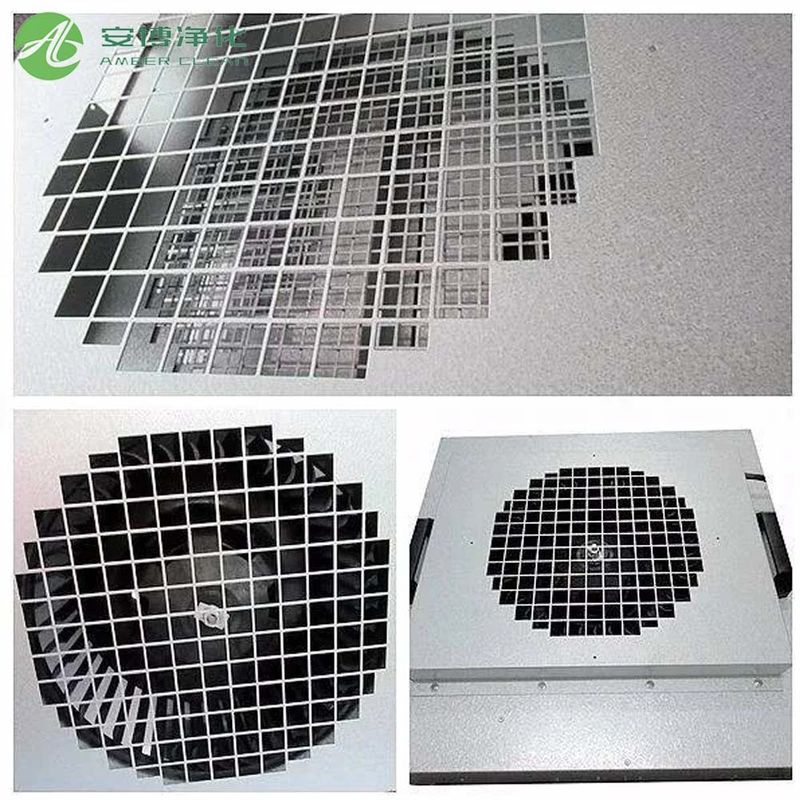

FFU is equipped with primary and high-efficiency two-stage filters. The fan inhales air from the top of the FFU and filters it through the primary and high-efficiency filters. The filtered clean air is uniformly delivered at a wind speed of 0.45m/s ± 20% on the entire outlet surface. Or other wind speeds or sizes you want can also be customized.

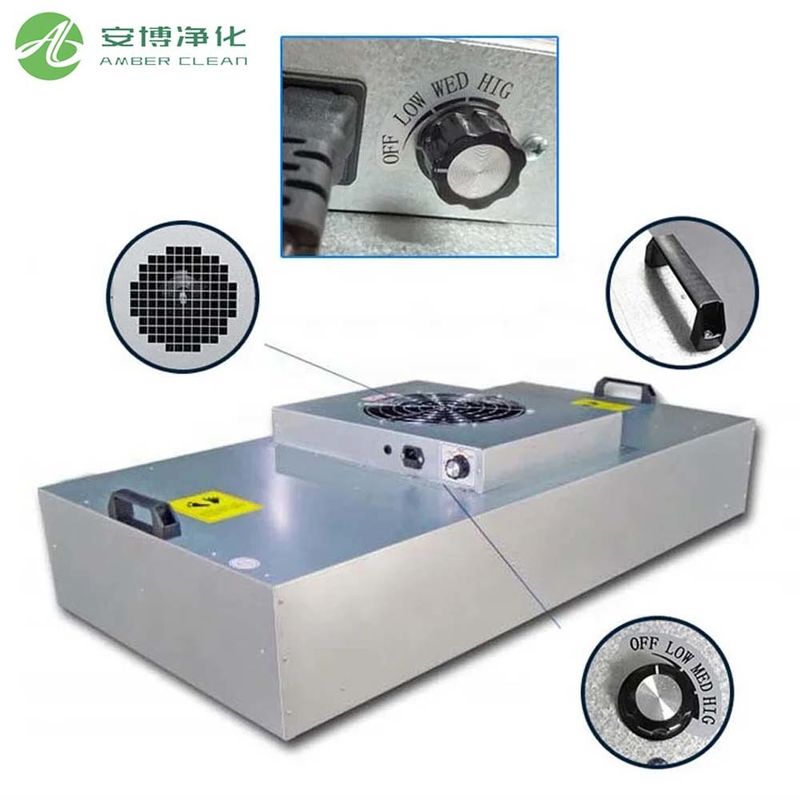

Basic structure of FFU box

FFU is mainly composed of four parts:

1. Box

The materials are usually galvanized aluminum alloy coated steel plate, aluminum alloy, and stainless steel. The first function is to support the fan and air guide ring, and the second is to support the guide plate.

2. Guide plate

The air flow balance device is built into the box, around the bottom of the fan.

3. Fan

There are three types: single-phase AC (AC/1Phase), DC (EC/1Phase), and three-phase AC (AC/3Phase).

4. Control components

For AC FFU, it usually uses a five-speed speed regulator or a stepless speed regulator; the control chip of the DC system is embedded in the motor, and remote control is achieved with the help of special control software, computers, control gateways and network lines.

FFU Application

- Cleanroom systems include: Duct system, FFU system and axial flow fan system.

- Advantages: Flexibility, reusability, negative pressure ventilation, shorten construction period, reduce operating costs and save space.

Cleanrooms with cleanliness levels above Class 1000 or ISO6 usually adopt FFU layout, and local purification environments or clean cabinets, clean workbenches, etc. are usually achieved with FFU.

Fan Filter Unit Specifications

| Model |

FFU-500 |

FFU-1000 |

FFU-1500 |

FFU-2000 |

|

out size mm

(W*L*H)

|

575*575*230 |

575*1175*230 |

875*1175*230 |

1175*1175*230 |

|

Filter size mm

(W*L*H)

|

570*570*69 |

570*1170*69 |

870*1170*69 |

1170*1170*59 |

| Air flow |

500m³/h |

1000m³/h |

1500m³/h |

2000m³/h |

| Pressure |

210Pa |

210Pa |

220Pa |

230Pa |

| Power |

170W |

170W |

210W |

275W |

| Noise |

47-55dB |

47-55dB |

50-58dB |

50-58dB |

| Weight |

27KG |

34KG |

46KG |

55KG |

| Cleanliness |

Class 100 (ISO 14644-1) |

| Material |

Stainless steel/ Galvanized steel/ Coated steel |

| Voltage |

AC 220V/50HZ AC 380V/50HZ |

FAQ

Q1: Does the installation of Filter Fan Units require a ceiling?

A: Yes. FFU equipment is usually installed in the aluminum profile ceiling or T-shaped keel ceiling of the clean room. The ceiling structure must have sufficient load-bearing capacity and reserve equipment inspection ports and inspection space to facilitate later maintenance and HEPA filter replacement. It is recommended to determine the Fan Filter Unit installation plan during the clean room design phase to avoid later adjustments.

Q2: What cleanliness levels does this FFU support?

A: AMBER Class 100 Galvannized Steel 46KG Filter Fan Unit is suitable for clean room environments of different levels such as Class 100, Class 1000, and Class 10000. By adjusting the air volume and configuring different filters, it can be flexibly used in a variety of clean demand places such as medical, pharmaceutical, electronic, and laboratory.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!