Amber professionally provides you with customized 100mm thick Wall Sandwich Panels, which are tailored for medical clean space and cold storage environment to ensure the space environment is stable, clean and safe.

What are the advantages of Wall Sandwich Rock Wool Panel?

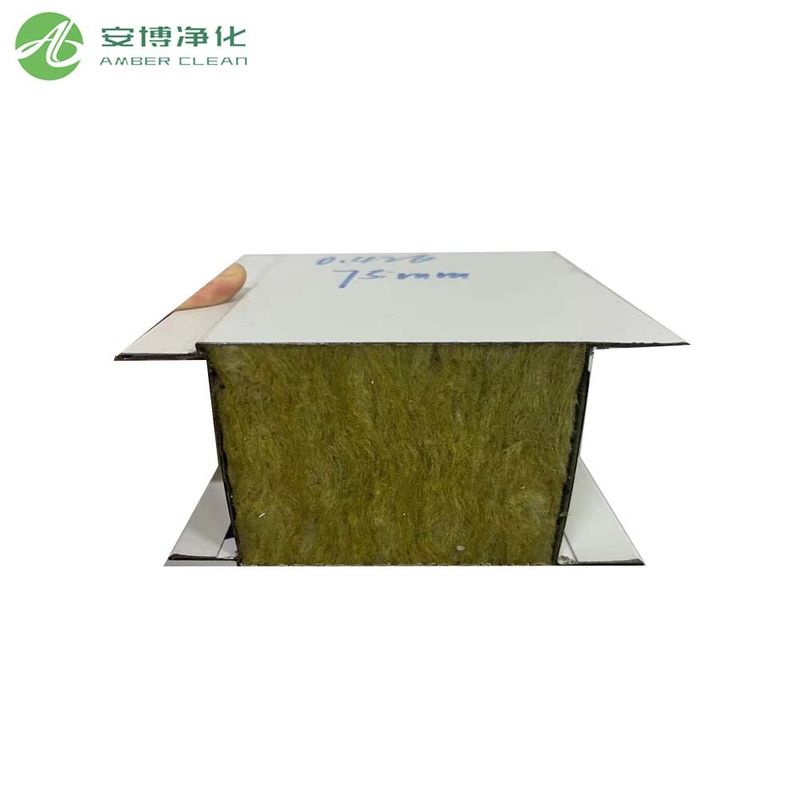

This custom wall sandwich Rock Wool Panel is filled with high-density rock wool in the core, with low thermal conductivity, which effectively isolates the conduction of cold and heat. The advantages are as follows:

1. Good thermal insulation performance: Since the sandwich sandwich panel exterior wall panel is filled with thermal insulation materials such as rock wool, rigid foam plastics, etc., these materials have good thermal insulation performance, which can effectively reduce the transfer of indoor and outdoor temperature and improve the thermal insulation effect of the building.

2. High strength and good rigidity: The sandwich sandwich panel exterior wall panel consists of two layers of metal sheets inside and outside and the thermal insulation material in the middle. The Wall Sandwich Panels structure has high strength and rigidity, can withstand the effects of external loads and natural forces such as wind, and ensure the safety and stability of the building.

3. Good fireproof performance: The insulation materials used in sandwich panel exterior wall panels are mostly inorganic materials, such as rock wool, glass wool, etc. These materials are not easy to burn and have good fireproof performance, which can effectively improve the fireproof level of the building.

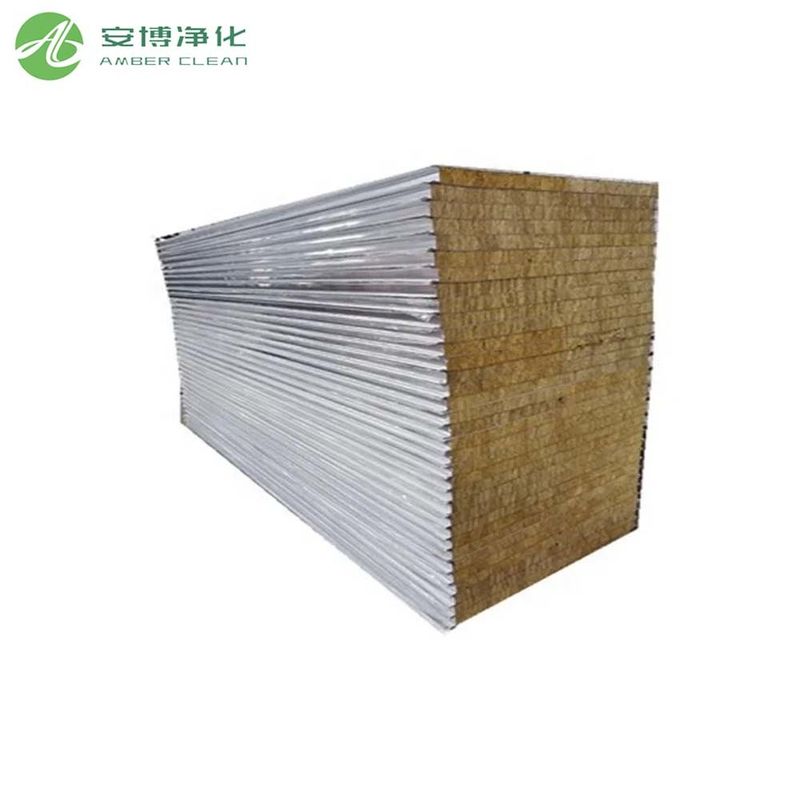

4. Convenient and fast construction: The Sandwich Panel exterior wall panels are made in a prefabricated manner, which can be mass-produced in the factory. The on-site installation is convenient and fast, which greatly shortens the construction period and improves the construction efficiency.

5. Beautiful and elegant: The surface of the sandwich panel exterior wall panels is flat and bright in color. It can be customized according to different needs, such as choosing different colors and textures, etc., to make the appearance of the building more beautiful and elegant.

Application scenarios and customer groups

Custom Wall Sandwich Panels are commonly used in modular operating rooms, ICU intensive care units, pharmaceutical cleanrooms, food processing plants, electronic semiconductor cleanrooms, and refrigerated and frozen warehouses. They can effectively improve indoor temperature control and fire protection performance and ensure surgical safety.

Our customers include medical institutions, pharmaceutical factories, cold chain storage companies, electronic factories, and large food processing groups, and are widely praised. For example, cold chain logistics companies, chain restaurant groups, and food preservation warehouses also often use 25mm Cold Room Panels and thick sandwich panels to build cold storage and constant temperature warehouses to ensure food safety and environmental stability.

Specifications

| Sandwich panel |

Double Steel + Rock wool filler |

| Fire proofing |

A |

| Weight capacity |

80kg/㎡ |

| Size |

1150/1180mm width, height customized |

| Steel thickness |

0.376mm, 0.426mm, 0.476mm, 0.526mm, 0.576mm |

| Thickness |

50mm, 75mm, 100mm |

| Installation |

1. we send engineer to customer side

2. construct out to construction team

3. customer send tachnicist to our company for free studying

|

FAQ

Q1: What is the fire rating of rock wool sandwich panels?

A: The core material of the Wall Sandwich Rock Wool Panel we use is Class A non-combustible rock wool, which has excellent fire resistance, can effectively prevent the spread of fire and ensure space safety.

Q2: What size of wall panels can be customized?

A: Customized thicknesses of 25mm, 50mm, 75mm, 100mm and other specifications are supported, with a maximum length of 12 meters and a standard width of 1150mm to meet the needs of different clean spaces and cold storage projects.

Q3: How to install this type of wall panel?

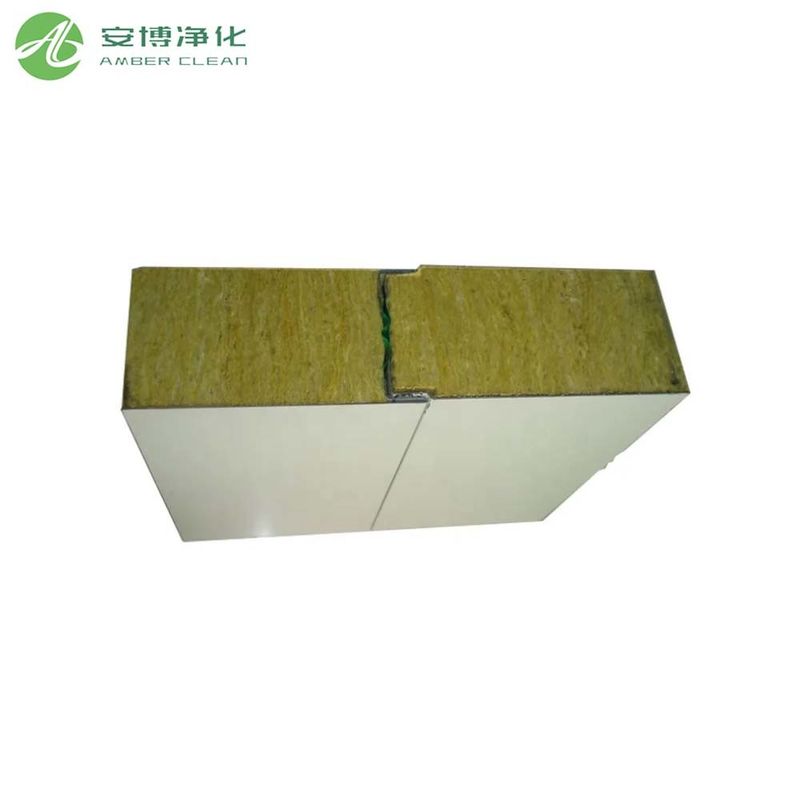

A: The wall panel adopts a plug-in splicing structure, which is easy to install and has good sealing. It can effectively shorten the construction period and is suitable for clean room and cold storage fast installation projects.

Case

Cleanroom

Operating Theatre

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!