Air Handling Unit (AHU), also often called air conditioning box or wind cabinet, is an indispensable equipment in central air conditioning system. It drives air flow through fans, so that indoor air exchanges heat with the coil in the equipment, and performs multiple filtration on the air, thereby adjusting indoor temperature, humidity and air cleanliness to create a healthy and comfortable environment.

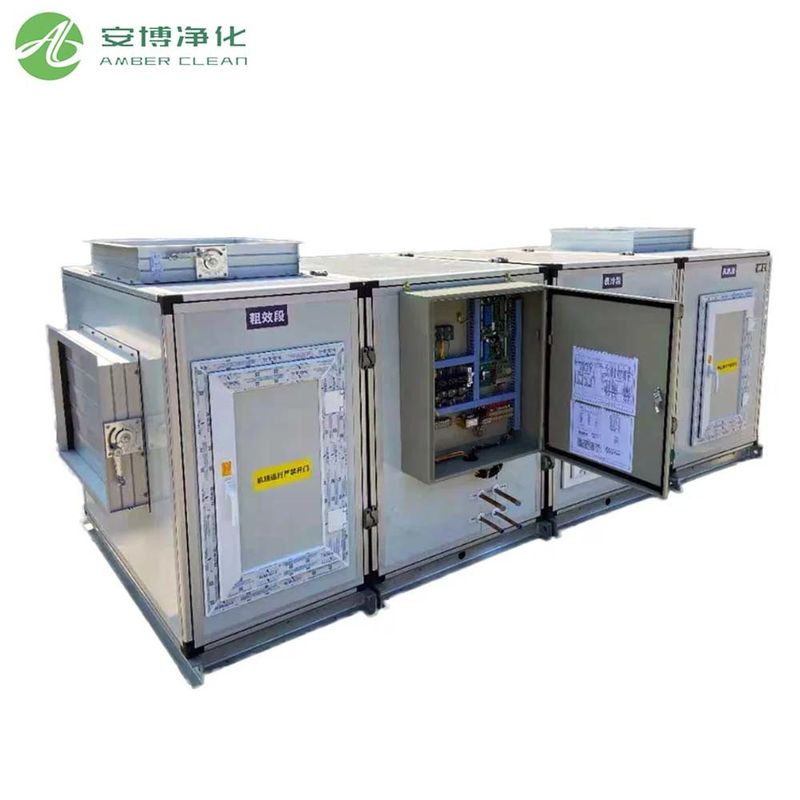

Compared with traditional air conditioning equipment, this Custom Air Handling Units not only has standard fresh air, air supply, return air, filtration, cooling, heating, humidification and other functional segments, but also can be flexibly customized vertical or horizontal structure according to user project requirements to meet application scenarios in different building spaces and process environments.

Product structure and function

Our customized air handling unit adopts modular design. It can freely combine the following functional sections according to actual use needs. Each part uses high-quality Air Handling Unit Components to ensure long-term stable operation of the system:

Fresh air section

Responsible for introducing outdoor fresh air, and realizing fresh air volume adjustment through air valve and fan linkage. It is recommended to install temperature sensors to monitor outdoor ambient temperature and realize intelligent control.

Filter section

Equipped with primary filter and medium filter, dust impurities of different particle sizes are intercepted and filtered step by step. If used in clean environment, sub-high efficiency and high efficiency filters can also be added. All filter sections are equipped with differential pressure switches to monitor the filter status in real time to ensure clean air supply and system safety.

Return air section

Realize the reasonable mixing of indoor return air and fresh air, automatically adjust the return air volume, intelligently optimize the return air ratio according to the outdoor temperature difference in winter and summer, and improve the energy efficiency of the system. Temperature and humidity sensors are installed in the return air duct to provide data support for cooling, heating and humidification control.

Surface cooling section

The air is cooled and dehumidified by the chilled water surface cooler. Equipped with temperature control valve and antifreeze protection switch, it can effectively prevent the equipment from being damaged by low temperature and ensure the safe and stable operation of the system.

Heating section

It is used for reheating after air heating or dehumidification in winter, and supports hot water coil heating or electric heating. The two-pipe system uses a common surface cooler for heating and cooling, saving pipe installation space.

Humidification section

It meets the humidity requirements of winter air drying or special processes, with standard wet film humidification and optional steam humidification. It effectively improves indoor air comfort.

Air supply section

The core fan section is responsible for evenly delivering the treated air to each room. The air valve and fan are interlocked to ensure stable and smooth air supply.

Product advantages

- Customizable design: Supports a variety of sizes, air volumes, and functional section combinations to meet the application needs of different places such as hospitals, laboratories, electronic workshops, food workshops, and office buildings.

- Energy saving and high efficiency: Intelligent return air ratio adjustment and optimized heat and humidity treatment functions effectively reduce operating energy consumption.

- Cleanliness guarantee: Multi-stage filtration scheme, combined with pressure difference monitoring, guarantees the quality of clean air supply, especially suitable for clean workshops and laboratory environments.

- Safety and stability: Complete anti-freeze, anti-blocking, over-temperature, and pressure difference alarm systems extend the service life of the equipment.

Application Scenarios

This series of Custom Air Handling Units is widely used in a variety of central air conditioning system projects such as medical clean areas, pharmaceutical workshops, food production, laboratories, office buildings, shopping malls, hotels, airport terminals, etc. It is also the customized air handling equipment recommended by many Air Handling Unit Manufacturers for large projects.

FAQ

Q1: What functions can be customized for your AHU?

A: Of course! As professional Air Handling Unit Manufacturers, we support customization of multiple functional modules such as fresh air section, filtration section, return air section, surface cooling section, heating section, humidification section, air supply section, etc., which can be combined into Vertical or Horizontal Air Handling Units. Parameters such as air volume, filtration level, coil type, humidification method, etc. can also be customized according to project requirements.

Q2: How many levels of filtration are there in the filtration section of AHU? How often do I need to replace the filter?

A: It is usually divided into primary filtration, medium efficiency filtration, (optional) sub-high efficiency and high efficiency filtration. Different cleanliness requirements correspond to different filtration configurations. The filter replacement cycle depends on the on-site use environment. It is generally recommended to check the primary filter every 3 months, the medium efficiency filter every 6 months, and the sub-high efficiency and high efficiency filters according to the differential pressure gauge or differential pressure switch alarm prompts to ensure air purification.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!